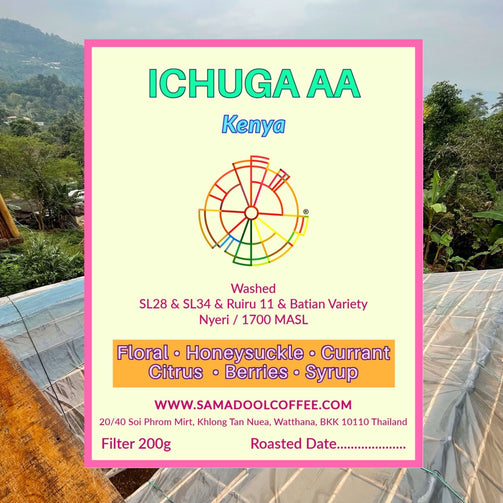

Ichuga AA ( Filter Roasted )

Ichuga AA ( Filter Roasted )

- Regular price

- 690.00 ฿ THB

- Regular price

-

- Sale price

- 690.00 ฿ THB

- Unit price

- per

COUNTRY: Kenya

REGION: Central Kenya

COUNTY: Nyeri County

FACTORY: Ichuga

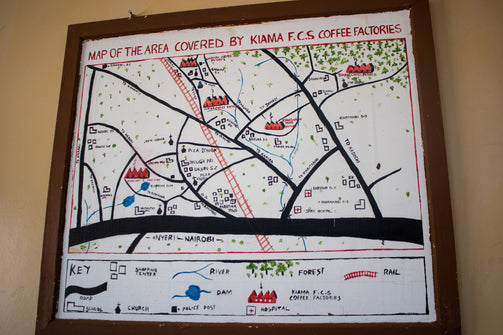

FARMERS COOPERATIVE SOCIETY: Kiama FCS

FACTORY MANAGER: Stephen Kinyua

FACTORY ELEVATION: 1,790 meters above sea level

FARMERS: 835 smallholder producers

AVERAGE FARM ELEVATION: 1,700 meters above sea level

AVERAGE FARM SIZE: Half a hectare

VARIETY: SL28, SL34, Ruiru 11, Batian

COFFEE GRADE: AA

PROCESSING: Washed

All the coffee cherry is hand-picked and delivered on the same day to the washing station, where it undergoes meticulous sorting. The coffee is then placed in a receiving tank and pulped using a four-disc pulping machine to remove the skin and fruit from the inner parchment layer that protects the green coffee bean. After being pulped, the coffee is sorted by weight using water, with the highest quality and densest beans being separated out from the lighter, lower-quality beans.

The coffee is then dry fermented for 20–24 hours, to break down the sugars and remove the mucilage (sticky fruit covering) from the outside of the beans. Whilst the coffee is fermenting it is checked intermittently and when it is ready it is rinsed and removed from the tanks and placed in a washing channel. The parchment-covered coffee is then washed with fresh water (mainly coming from a natural well located onsite) and sent through water channels for grading by weight. The beans are then sent to soaking tanks where they sit underwater for a further 24 hours. This process increases the proteins and amino acids, which in turn heightens the complexity of the acidity.

After soaking, the coffee is pumped onto deep drying beds where they drain for 1-2 hours, before being transferred to raised drying tables (also known as African beds). As they dry the parchment is turned constantly to ensure even drying, and so that any defective beans can be identified removed. Time on the drying tables depends on the weather, ambient temperature and processing volume: taking anywhere from one to three weeks to get to the target moisture of 11–12%. After drying the coffee is moved to conditioning beds, where it rests in parchment for about a month. This resting period helps to stabilise water activity and contributes to long-lasting quality and vibrancy in the cup.

RECOMMENDED Suitable for Filter brewing methods and French press.

**NOTE FOR DELIVERY** An order placing BEFORE 2 PM will arrange on next day delivery. An order AFTER 2 PM will deliver on the next following days.

Couldn't load pickup availability